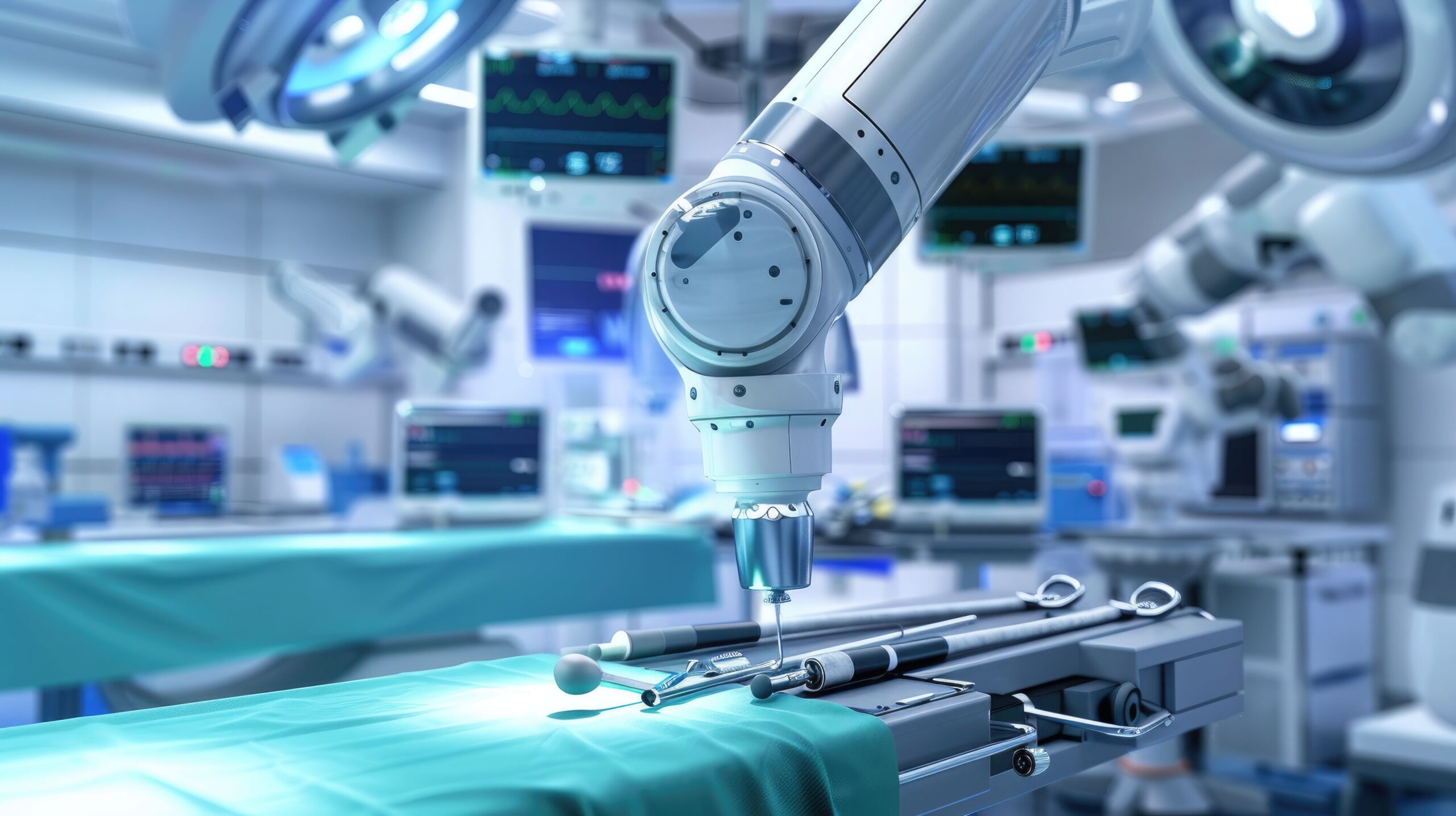

Precision CNC Machining for Medical Devices

At MetalQuest Unlimited, our advanced CNC technology and dedication to high-quality standards position us to become a leader in the production of medical components. Our approach ensures that every product meets the rigorous demands of the healthcare industry.

-

Turn-Key Solutions

The medical industry requires precision and dependability. Our turn-key solutions cover every aspect of your manufacturing needs—from design and prototyping to full-scale production and regulatory compliance. With MetalQuest handling the details, you can focus on delivering life-saving products with confidence.

-

Advanced Machining Technology

Our state-of-the-art CNC machines, including multi-axis milling, mill-turn, and Swiss CNC machining, deliver unparalleled precision for intricate medical components. By utilizing both Esprit and Fusion 360 CAD/CAM systems, we optimize programming efficiency and ensure precise machining for even the most complex geometries.

-

Commitment to Quality Control

Quality control is a foundational pillar of our company. Our advanced Coordinate Measuring Machines (CMMs), integrated with Esprit and Fusion 360 systems, validate component accuracy at every step of production. This ensures compliance with industry regulations and meets the exacting standards required by our clients in the medical sector.

-

Customer-Centered Collaboration

We will work closely with medical device manufacturers to understand their unique needs. Whether you're developing custom surgical tools, implants, or diagnostic components, MetalQuest provides tailored solutions to meet tight tolerances and surface finish requirements. We can work with biocompatible materials such as 316L stainless steel, PEEK, and special alloys, ensuring safety and durability.

Medical Machining Materials

We understand the critical role material selection plays in medical manufacturing. MetalQuest works with a wide variety of biocompatible and high-performance materials, each tailored to meet the specific needs of your medical components.

METALS

-

Stainless Steel (316L)

-

Cobalt-Chrome Alloys

-

Titanium and Titanium Alloys

-

Nickel Alloys

Plastics

-

Medical Grade Plastics

Custom Medical Components

In the medical field, precision and reliability are paramount. MetalQuest has the capability to produce custom medical parts that meet the exacting standards of the healthcare industry. From surgical instruments to spinal fixation components, our advanced machining capabilities and stringent quality controls ensure that your products are delivered with accuracy and dependability.

-

Precision CNC Machining:

Expertise in machining complex medical components to tight tolerances.

-

Custom Medical Parts:

Tailored to your specific design requirements.

-

Surface Finish & Coatings:

Advanced finishing options to meet sterilization and aesthetic needs.

-

Scalable Production:

From prototyping to full-scale production, we adjust our processes to meet your volume demands.

Let’s Discuss Your Project Needs

Partner with MetalQuest Unlimited for your medical machining needs. From custom medical components to precision CNC machining, we have the expertise to meet the stringent demands of the healthcare industry. Contact us today to learn more about how we can support your projects with tailored solutions and uncompromising quality.

Why Choose MetalQuest Unlimited for Medical Machining?

Medical device manufacturers should choose MetalQuest Unlimited for our dedication to precision, quality, and on-time delivery. Here’s why: